QUALITY CERTIFICATION

The quality policy keeps in line with the changing market conditions and the evolving customer needs. Achieving that goal, we keep on identifying the needs, product quality and diversity of the industry with an innovative and competitive perspective.

Being leaders and accomplishing our client’s needs and specifications without compromising the product’s quality and complying with laws and regulations are our main goals: it is our way to create a long-term business partnership.

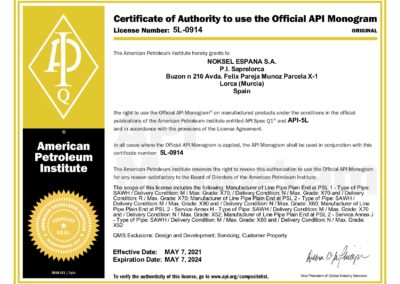

All employees encourage their professional improvement in terms of knowledge, skills and training. In Noksel España we keep teamworking and improving our teamplay, maintaining our quality and working in an innnovative way by the quality management system with ISO 9001 and API Q1.

Should you need any further information, please do not hesitate to contact us: ventas@nokselspain.com

QUALITY CONTROL

Noksel España has a quality control system including all production processes starting from raw material, continuing with welding wire and flux, and until transportation procedure.

The system is managed by a computer-based software which prevents human error in a great extent.

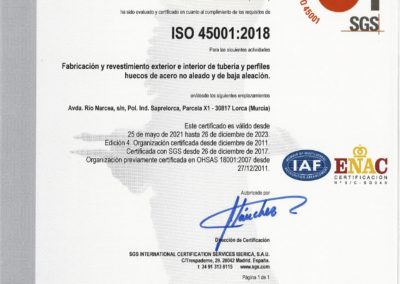

Our company, by establishing a detailed Quality ISO 9001, Environment ISO 14001 and Occupation Health and Saftey OHSAS 18001 management systems, aims to be a leader in its own market competition.

Quality control is one of the most important functions. All the required tests and inspections are carried out in compliance with the customer requirements and related standards by using modern inspection and testing equipments.

Water pipe lines

- EN 10224

- AWWA C200

- EN 10217-1

Pipe joints and specials

- AWWA C208

- BS 534

Oil&Gas pipe lines

- API 5L

- ISO 3183

- EN 10208-2

Piling pipes

- EN 10219-1

- ASTM A 252

General purpose pipes

- EN 10217-1

- EN 10217-3

- EN 10217-5

- EN 10217-6

MAIN QUALITY TESTS

Hydrostatic test

Non-destructive tests

- Online AUT inspection.

- Radioscopic test.

- Offline AUT inspection.

- Manual ultrasonic inspection (UT).

- Magnetic particle inspection (MT).

- Dye penetrant inspection (PT).

- Real-time X-ray radiographic inspection.

- Visual inspection (VT) and dimensional check.

Mechanical laboratory tests

- Chemical analysis.

- Tensile test.

- Guided-bend test.

- Impact test (Charpy).

- Drop weight tear test (DWTT).

- Hardness test.

- Metallographic test.

Coating laboratory tests

- Elongation at break test.

- Impact resistance test.

- Adherence test after immersion in water test for polyethylene/polypropylene coating.

- Adherence test for epoxy coating by grid cut.

- Adherence test for epoxy/polyurethane coating by pull-off or V-cut.

- Cathodic disbondment resistance test.

- Flexibility test.

- Continuity (holiday detection) test.

- Melt flow rate measurement test.

- UV light ageing test.

- Thermal ageing test.

- Porosity test on coating on glass pannel.

- Bending/flexibility test in connical mandre for epoxy coating.

- Disbonding test for coating after immersion in water/solvent.

- Thermal analysis by DSC for characterization of uncured epoxy and FBE.

- Detection in surface of salt contamination test.

HEADQUARTERS

Av. Mediterráneo, 5 – 1ºG

28007 Madrid (MADRID)

SPAIN

Tel: +34 91 535 17 90

Fax: +34 91 534 69 42

Email: nokselspain@nokselspain.com

LORCA FACTORY

Autovía del Mediterráneo Km. 644

Plg. Ind. Saprelorca, Buzón 216, Parcela X-1

30817 Lorca (MURCIA) SPAIN

Tel: +34 968 92 50 02

Fax: +34 868 10 48 96

E-mail: nokselspain@nokselspain.com

CONTACT

Domestic projects:

E-mail: ventas@nokselspain.com

International projects:

E-mail: export@nokselspain.com